With our state-of-the-art facilities, advanced production capabilities, and expert team, we can produce kitchenware items made from a wide range of materials—all under one roof. We streamline the production process to ensure high-quality products, reduced lead times, and seamless communication. From stainless steel to ceramics, we’re your trusted partner for all your in-house kitchenware needs.

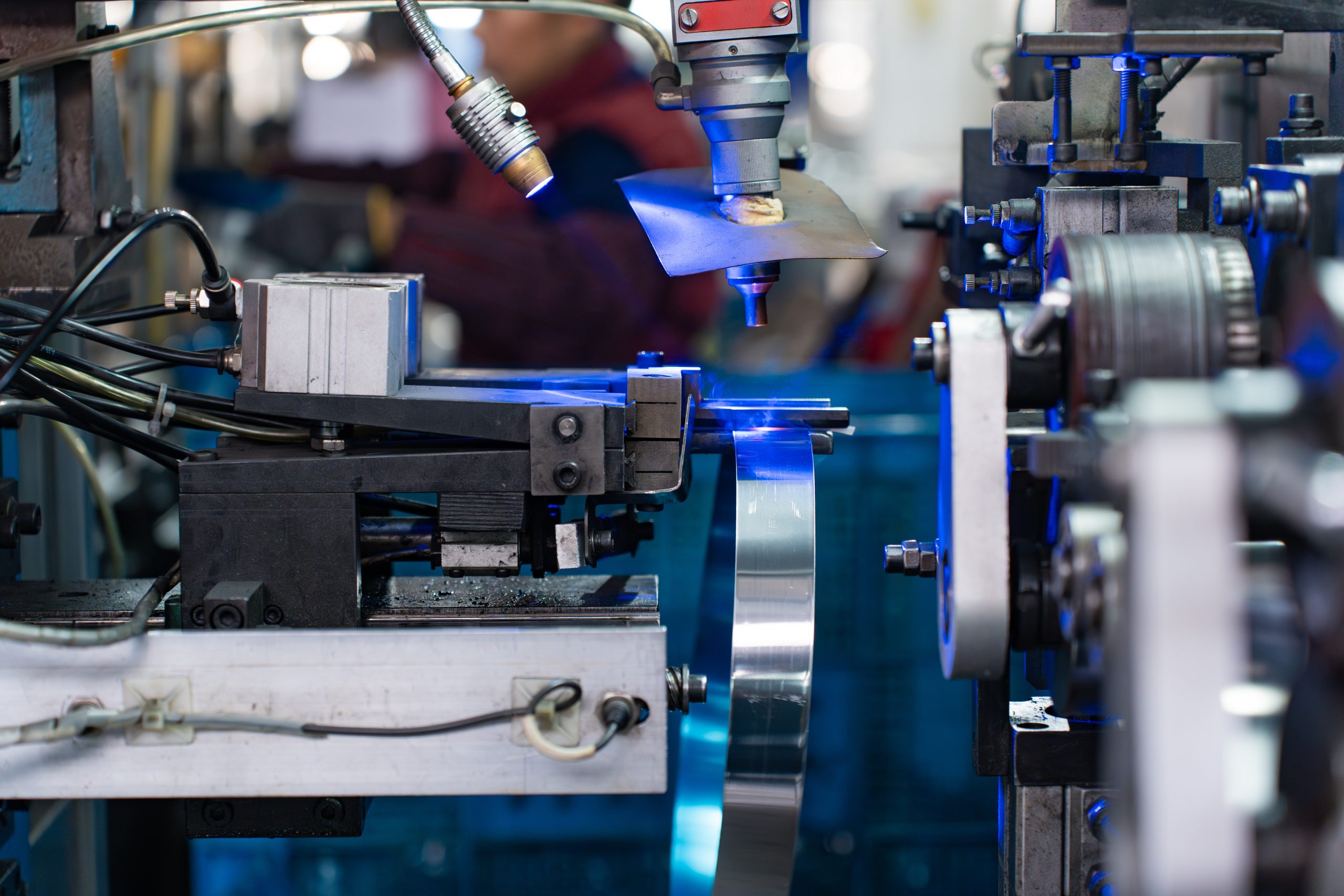

Minko’s stainless steel kitchenware stands out for its corrosion resistance, durability, and high strength. Our factory utilizes advanced manufacturing and polishing techniques to produce smooth, long-lasting products.

With strict quality control and precise metalworking processes, we ensure each piece is rust-resistant and built to withstand high temperatures and heavy use.

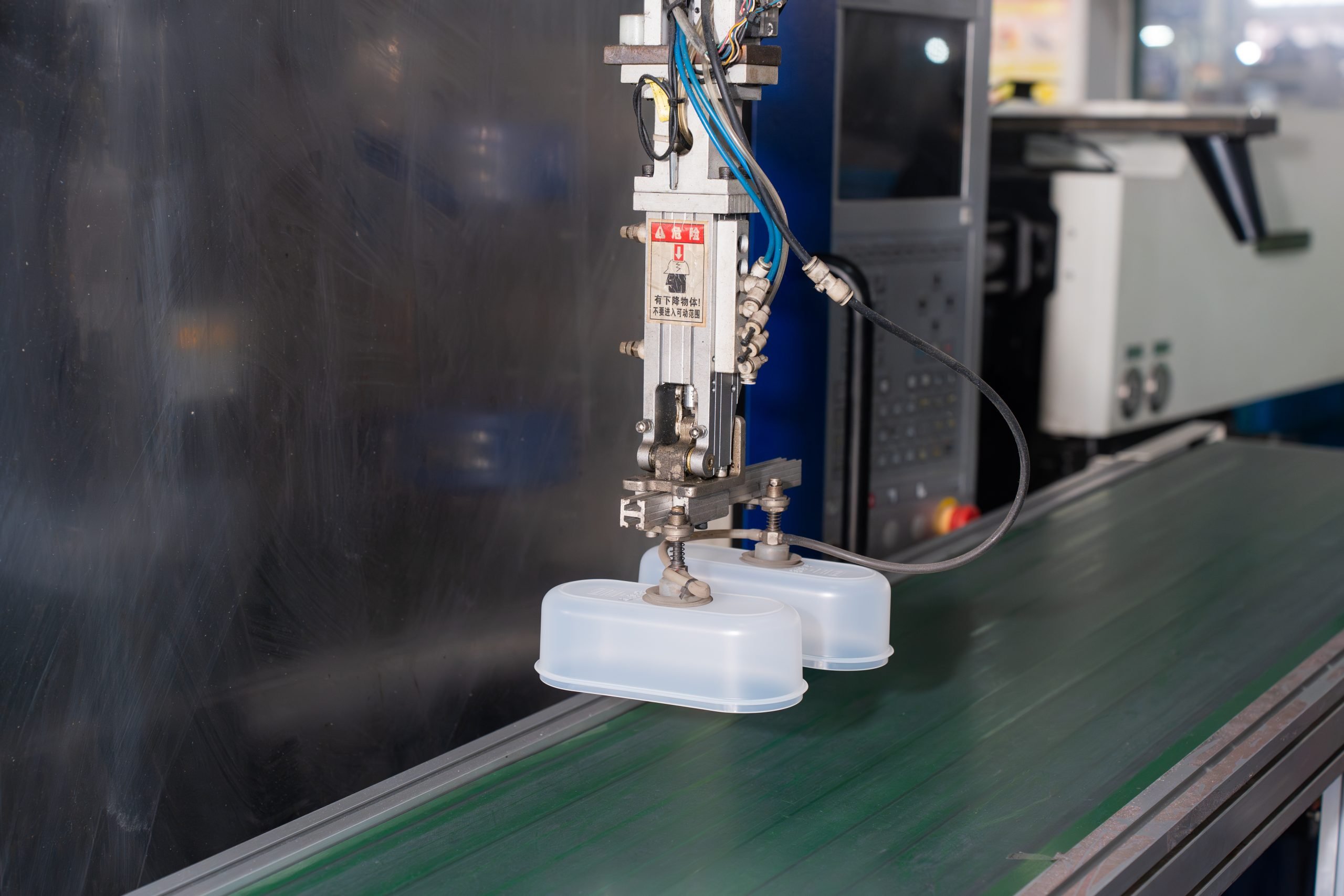

Silicone kitchenware offers flexibility, heat resistance, and safety. Using injection molding and compression molding techniques, our factory produces items with precise shapes and smooth textures.

Our silicone products undergo extended vulcanization to eliminate harmful substances, ensuring they are non-toxic, BPA-free, and capable of withstanding extreme temperatures.

Minko specializes in a range of plastic manufacturing processes, including the production of new plastics, recycled PET, and more. Our kitchenware products made from plastic are carefully cleaned, processed, and rigorously tested to meet our stringent quality standards.

Each material undergoes strict quality control to ensure durability, lightweight properties, and freedom from harmful substances.

Additionally, our recycled plastic materials are fully traceable, with Test Certificates (TC) available to verify both quality and compliance with industry standards.

Minko employs advanced molding and firing techniques to ensure each ceramic product has a high-quality finish, is chip-resistant, and can withstand high temperatures. The glazing process not only enhances the aesthetic appeal but also provides functional benefits, making the products easy to clean and maintain.